The Basic Principles Of DTF Transfer

The Basic Principles Of DTF Transfer

Blog Article

The transfer system is performed making use of warmth and stress. Once the PET film is positioned on to the fabric, the applied heat and pressure enable the ink to go through the PET movie and onto the fabric.

remedy: The movie containing the powdered structure really should be heated next to activate the adhesive powder. This can be attained in the utilization of a heat press, curing oven, or conveyor dryer.

just after printing, a powdered adhesive is placed on the print though it’s nonetheless wet. The movie is then cured in an oven or warmth push, solidifying the adhesive.

To maintain the caliber of DTF transfers, people ought to stick to certain rules. Here are several essential steps:

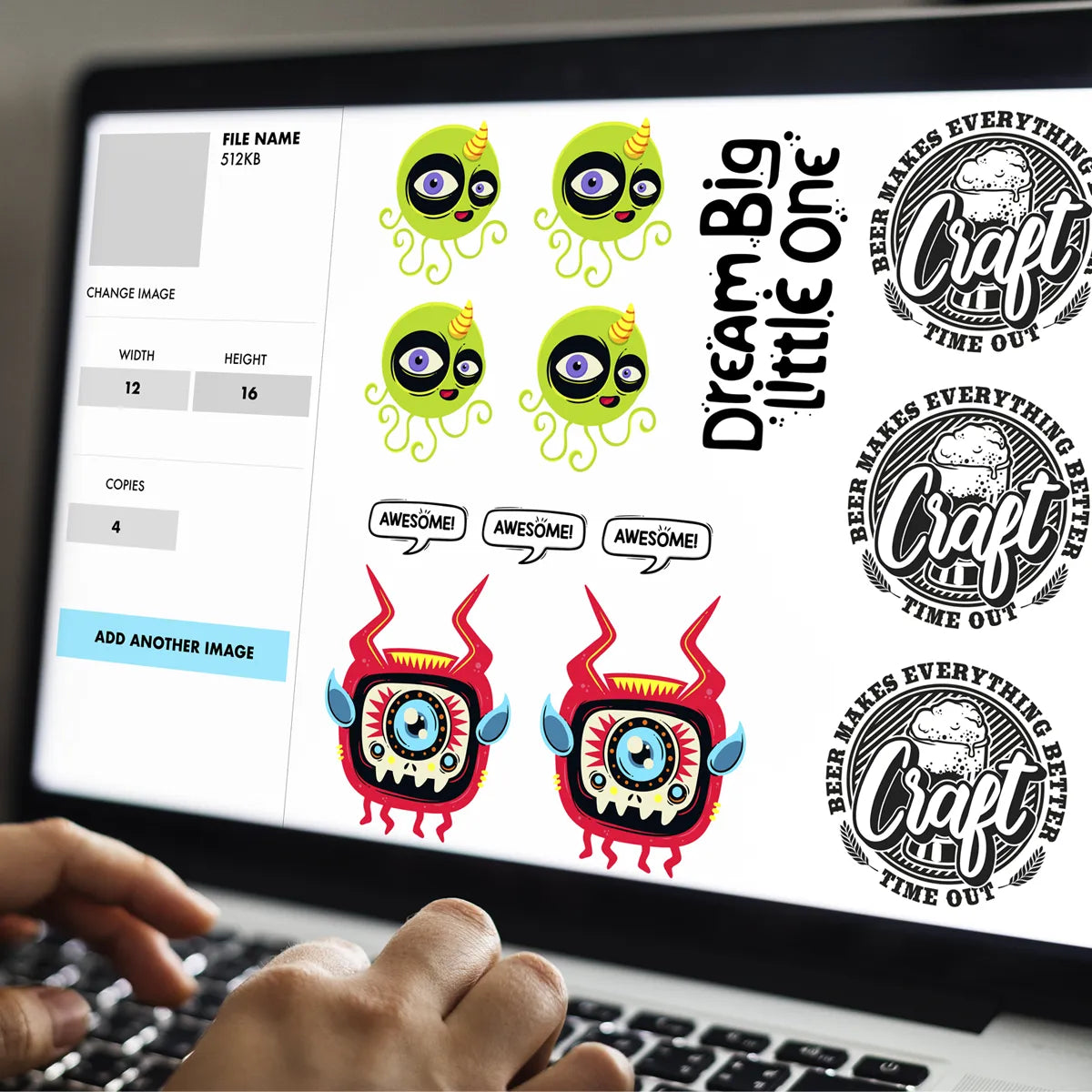

This portion addresses standard DTF supplies although guiding fans on print DTF transfers easily. Peruse the remainder of our top guidebook for further insights, together with an extensive DTF transfer placement information and frequently questioned queries.

This part sets the inspiration for understanding the way to print DTF transfers simply with Do it yourself techniques.

Powder: right after printing, though the ink remains to be soaked, a sizzling-soften adhesive powder is placed on the printed facet of your movie. This powder sticks to your wet ink and can eventually bond the design to the fabric.

4. Curing: The movie is then cured using a warmth press or oven. This phase is very important as it makes sure that the adhesive solidifies and the look is able to be transferred.

They're often known as DTF transfer films. When obtaining PET films, you'll find them in compact sheets for unique use or in huge rolls for enterprise uses, allowing you to choose the most fitted PET film on your operations.

just before we dive into some great benefits of DTF heat transfers, let’s initial outline whatever they are. DTF heat transfers absolutely are a variety of warmth transfer technological innovation that lets you print large-good quality, complete-shade patterns directly onto a transfer movie, which can then be heat pressed onto a garment.

This may be read more especially helpful for corporations that require to produce orders promptly or for the ones that provide rush orders. it is possible to deliver and ship orders a lot quicker, which may help you keep your prospects pleased and content.

How need to I preserve my artwork for DTF Printing? does one mirror artwork? Artwork should be saved at the highest high quality probable in CMYK coloration mode ( not RGB). Vector artwork is highly advised, although large-resolution raster images will also be acceptable as long as it's a transparent history.

Together with the ideas of DTF transfer placement at your fingertips, you have got the equipment to unlock your style prospective and produce awe-inspiring customized clothing. Remember to adapt your models to various garment sizes, and embrace the synergy amongst print spots.

whether or not you might be new on the STAR method or taking into consideration a change towards the STAR credit, evaluation our resources for an entire overview.

Report this page